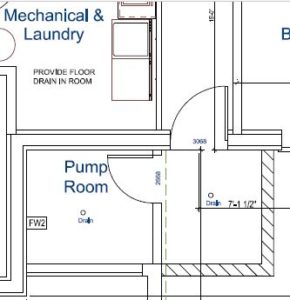

Yesterday, the RDOS inspector inspected the under slab plumbing and it was approved. The radeon collection work was also inspected – the poly seal was in place in 4 out of 5 bedrooms and radeon rock was being installed. Approval was given but the Builder needed to provide pictures after the work was completed. The perimeter drain tile and dampproofing also received an initial inspection; however, the geotech needs to do field review before approval will be given.

The Structural Engineer did an inspection today in preparation for pouring the slab which is planned for Monday starting at 8 am. Even though Monday is expected to be the coldest Dec 12th on record with the daytime high of -11 deg C and overnight low of -16 deg C (previous record low was -11 deg C), our Builder insists on going ahead. He has 3 large electric heaters running continuously to ensure the inside of the house will be warm enough for the pour.